Stamber gives great importance to the development of the design.

Since its establishment Stamber has always focused on technological innovation, example of this is the advanced know-how acquired over the years.

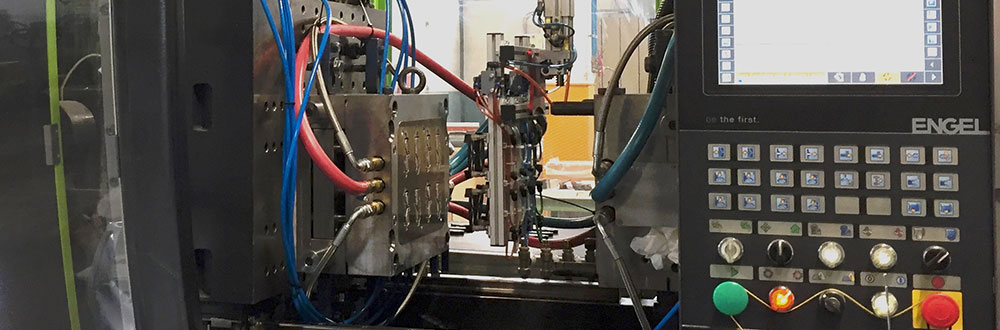

The knowledge of construction processes of molds and materials , together with the ability of exploiting the best molding technology, all this enables Stamber to face the realization of the product, in synergy with the customer , starting from an early stage of planning and process optimization , contributing in this way to define the constructive technical specifications and the use of the most suitable and performing plastic materials.

As preliminary steps, if requested by the customer, we offer a design consultancy service that provides analysis of all the functional and aesthetic aspects of the component, we then check the suitability of the project and the replacing design, so as to switch any metal parts with thermoplastic solutions.

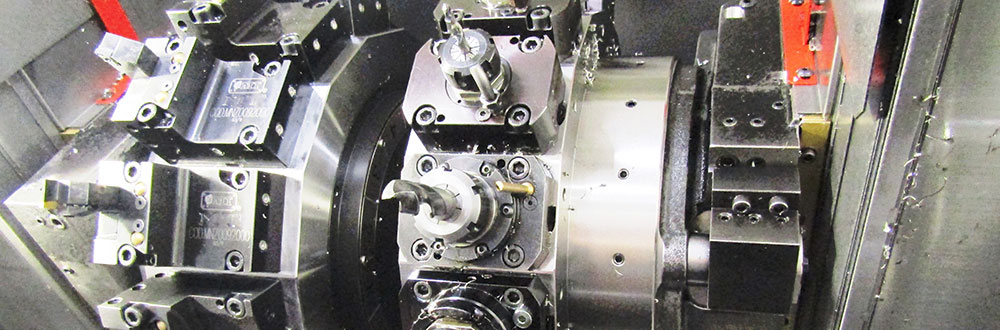

We carry out all phases of construction of the molds, the construction and the assembly of each component of the molds takes place entirely in our company in close contact with the technical department.

Our design/technical office employs technicians with proven experience, able to interact with the customer in order to make the product (co-design ) feasible , giving advice on all fronts.

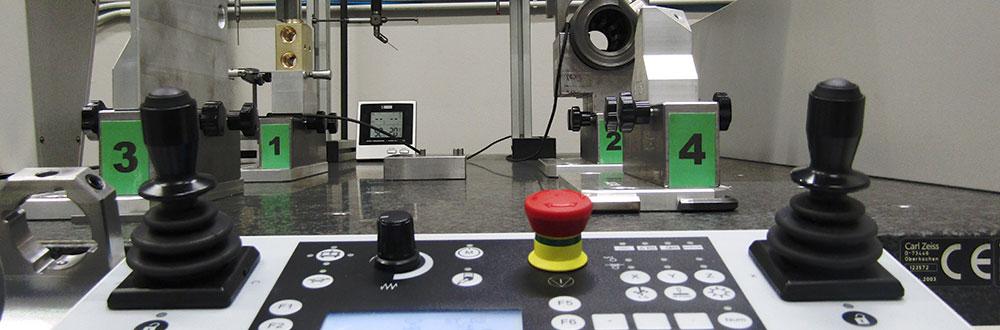

High experience in the use of the injection filling simulation systems (Mold-Flow), performed internally, allows Stamber to have information about the conditions of the molding process before the design.

These are essential data that have a direct impact on the final quality of the object and an economic return for the customer obtained by reduced times during the production parameters definition .

Stamber offers also a rapid prototyping service through machining and prototypes from pilot molds.